Thoughts about ‘Improving’

In the past many factory cartridges were converted by reducing body taper plus

creating a steeper shoulder for more powder space,

‘better’ powder burning and reduced

bolt thrust. Many can even use factory ammunition in the new chamber - a very

important aspect for P. O. Ackley . It is just that procedure we usually call

‘Improving’

.

Famous examples are the ACKLEY IMPROVED cartridges.

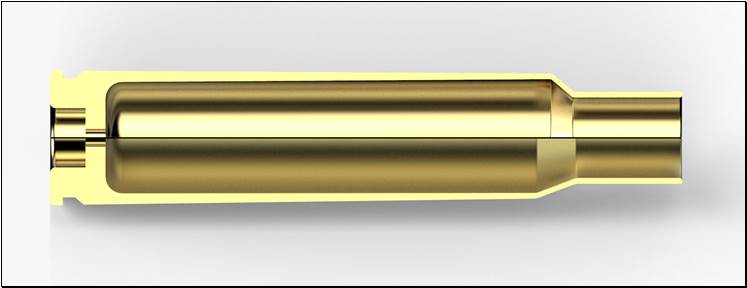

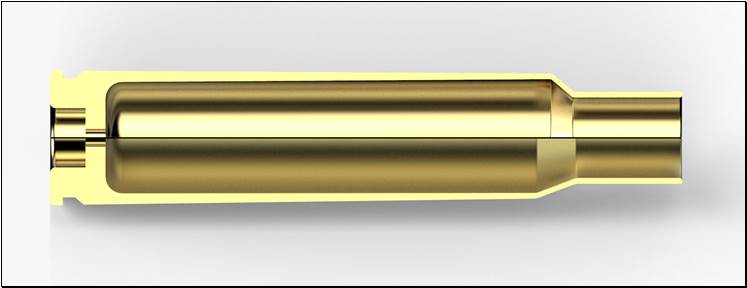

Another way to improve a factory case is extending the straightened body by

shortening the neck to a sufficient minimum. When you go that far you have to

think about assuring proper head space while fire forming. For that kind of

treatment the GIBBS cartridges are typical:

Some people are quite enthusiastic

about the performance or maybe too enthusiastic and some believe that little

real extra power is not worth the effort.

To get an impression of what you can expect when improving a case one should

look at some well known examples:

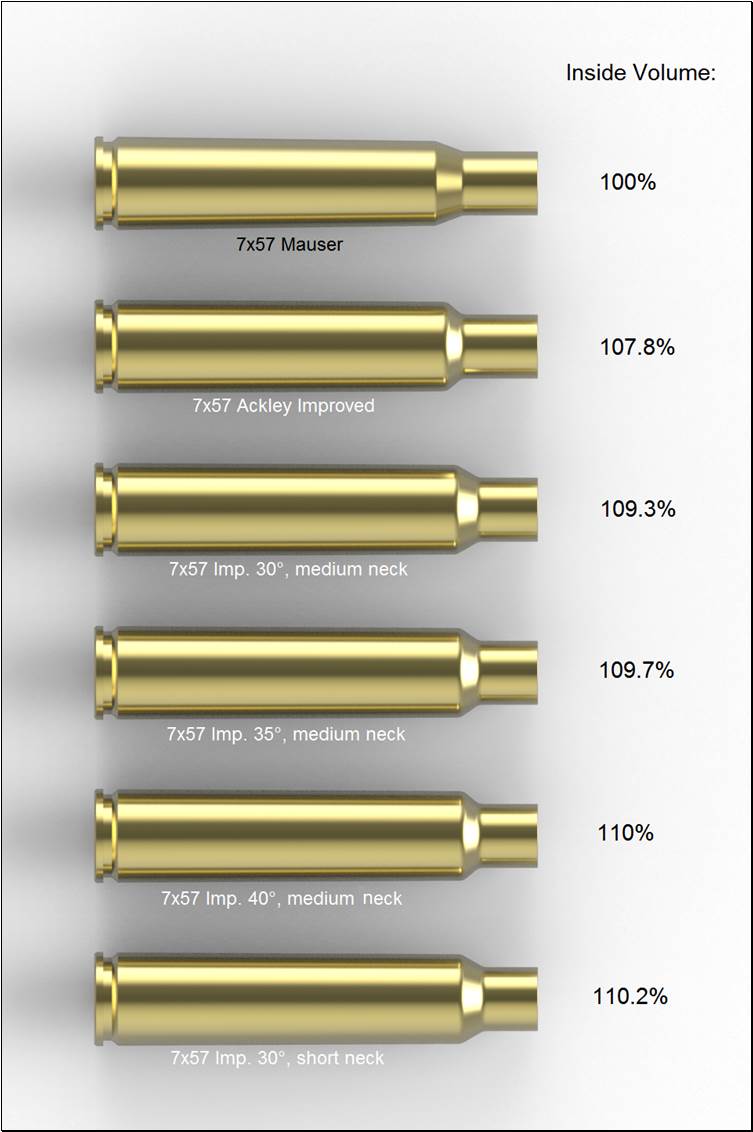

The 7x57Mauser is a typical

candidate for improving due to its long neck, long shoulder and old fashioned

body taper.

So let us see what the different ways of improving mean in real numbers as far

as powder space is concerned:

Calculations are based on identical case weight!

Using this example we can see that the most important step is reducing body

taper. Moving the shoulder comes second and increasing the shoulder angle comes

last. That would be different if the parent case has a very shallow shoulder

like the 300H&H.

If you combine a short neck and a shoulder angle of 40° you will get the largest

increase. That’s not very

surprising but would it be wise?

A long neck is good for accuracy. A neck length of one caliber or slightly more

seems to be a good compromise. A shoulder angle of 40° can lead to feeding

problems depending on actual proportions. The true benefit of a 40°shoulder for

powder burning – if any - can only be proved in comparison to a version with a

more gentle shoulder. It is reported that a 40°shoulder prevents the case from

stretching. This would be a real advantage.

When your parent case already has a rather cylindrical body and a large volume

your results will be more humble. See .30-06Springfield/.30-06Ackley Imp.:

Calculations are based on identical case weight!

4.2 % more powder space of the .30-06Ackley Imp. is not very impressive. That

may be the reason why this round is discussed a lot.

Unfortunately

Some published performance data of improved cartridges are really breath taking.

As we do not know much about the circumstances of these measurements we should

always be sceptical.

Most recently introduced factory cartridges have minimum body taper and large

shoulder angles. Improving these cases will be real challenging.

Probably the most successful Improving:

25-35 Ackley Improved:

Volume Difference: 24%